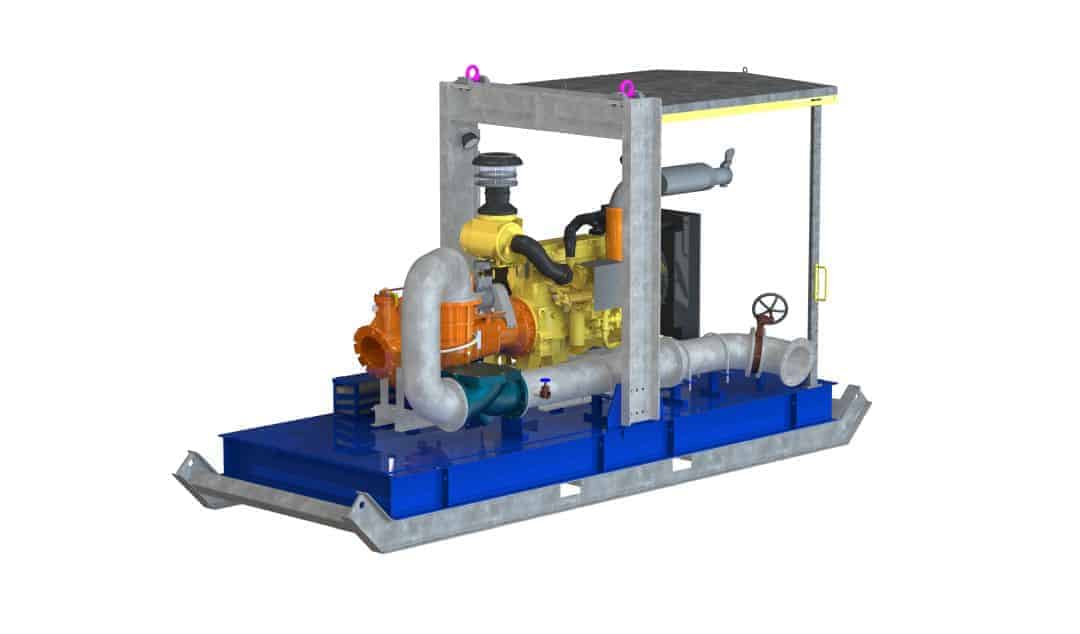

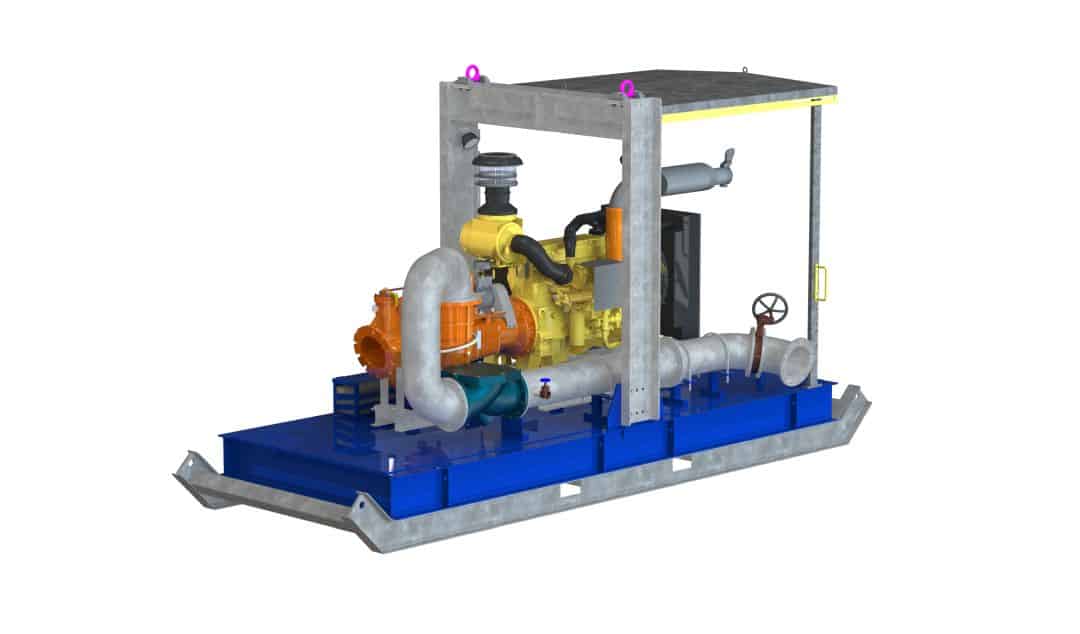

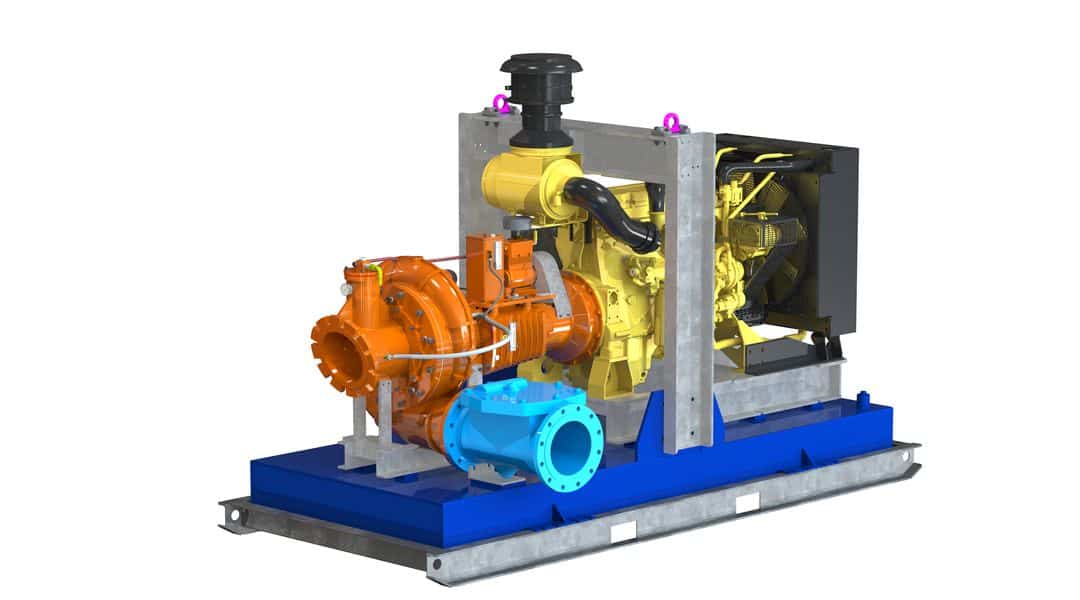

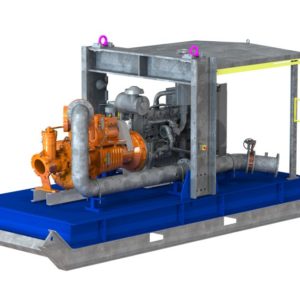

MH300-510

Innovations include the introduction of a flooded, oil-lubricated pump bearing set-up and leak-free pump bearing isolator in place of the grease lubrication system featured in many other pumps. This neatly sidesteps the usual threat of pump failure due to either too much or too little grease – or because of contamination.

- Closed coupled pump SAE # 1 – virtually eliminates pump / engine misalignment

- Flooded oil lubricated pump bearing set up

- Pump Bearing Isolator set up

- Excellent suction lift capabilities at high flow at variable diesel speeds (1,300 – 1,600rpm)

- Pump efficiency (77%)

The MH300 pump is available with an impeller diameter size of either 490mm or 510mm.

related products

Related products

WHY Sykes Group?

DIRECT COMMUNICATION

Our in-house engineers and tech experts will work with you to create bespoke solutions for your project.

PREMIUM SPECIFICATIONS

Our pumps are designed to handle the most challenging and demanding environments. Using our in-house engineering team, we can custom-design pump packages to match any specification.

OPERATION AND MAINTENANCE COSTS

We design and manufacture pump packages that delivers optimal efficiency and minimal downtime. Even operating in harsh conditions, our products provide a safe and cost-effective solution.

EQUIPMENT RANGE

We provide a wide range of pumps to handle all types of water-based issues. Whether above or below ground, Sykes Group can offer a solution.

CUSTOMER SERVICE AND AFTERMARKET

If you need advice on a particular part, our parts and customer service technicians are always available to offer qualified, professional advice.

STOCK AND MANUFACTURING

As the original equipment manufacturer (OEM), we keep plenty of stock on hand and can provide quick access to the parts you need.