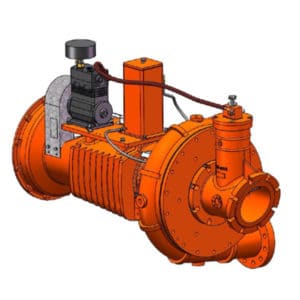

Diaphragm Priming System – Standard

Priming a pump is one of the most important processes to complete before a pump is operational.

The Diaphragm Priming System is suited to large mining projects, civil works and applications where environmental impact is a factor to name a few. It’s powerful air evacuation system will allow for quicker priming for long distance pumps.

- Higher air evacuation and vacuum capacity compared to Venturi compressor automatic self-priming options

- Float driven shut off valve mechanism

- Two-way valve activation mechanism

- Self-contained internal oil lubrication reservoir

- Rubber diaphragm (actuator and associated items) can be fixed or replaced onsite

related products

WHY Sykes Group?

DIRECT COMMUNICATION

Our in-house engineers and tech experts will work with you to create bespoke solutions for your project.

PREMIUM SPECIFICATIONS

Our pumps are designed to handle the most challenging and demanding environments. Using our in-house engineering team, we can custom-design pump packages to match any specification.

OPERATION AND MAINTENANCE COSTS

We design and manufacture pump packages that delivers optimal efficiency and minimal downtime. Even operating in harsh conditions, our products provide a safe and cost-effective solution.

EQUIPMENT RANGE

We provide a wide range of pumps to handle all types of water-based issues. Whether above or below ground, Sykes Group can offer a solution.

CUSTOMER SERVICE AND AFTERMARKET

If you need advice on a particular part, our parts and customer service technicians are always available to offer qualified, professional advice.

STOCK AND MANUFACTURING

As the original equipment manufacturer (OEM), we keep plenty of stock on hand and can provide quick access to the parts you need.