For many mining companies, the demand for higher-quality minerals is pushing them to dig deeper, offering both reward and risk. To safely extract these quality minerals, companies must have solid dewatering solutions. The introduction of the Extra High Head (XH) pump is helping to meet the demands of the mining sector.

Deep Mining and Water Management

Deep mining operations face a range of geological and technical challenges. Increased rainwater and groundwater ingress in mine pits and quarries demand efficient dewatering to maintain a safe environment.

It’s also vital for mining companies to understand the difficulties posed by some geological structures and how factors like altitude or air pressure will affect water management strategies. For mines that handle large volumes of water, it’s crucial to weigh up the positioning of the pumps and the depth and layout of the mine to maintain a reliable and efficient flow of water.

As you may expect, water at significant depths can contain various contaminants that will require treatment before being discharged. Mines must ensure they comply with environmental regulations, adding another layer of complexity to the dewatering operation. Then comes the need for a reliable power supply. A stable power supply and backup system are a must as mines dig deeper. Any system failure can result in rapid water accumulation, posing a risk to the mine and its workers.

Innovations in Pump Technology

To ensure mines and mine workers remain safe, pump manufacturers like Sykes Group have developed new pump technology that addresses the dewatering challenges in deep mining.

Mining companies have a variety of pumps to choose from for their deep mining operations, including:

High-Head and Extra High-Head Pumps

Able to move water over significant vertical distances. They generate high discharge pressures to lift water from great depths.

High-Flow Rate Pumps

Crucial in mines with substantial water ingress. They can remove large volumes of water rapidly to maintain operational continuity and safety.

Submersible Pumps

Effective for continuous dewatering operations. The submersible pumps are placed directly in the water.

How Sykes XH250 is Transforming Mining Dewatering

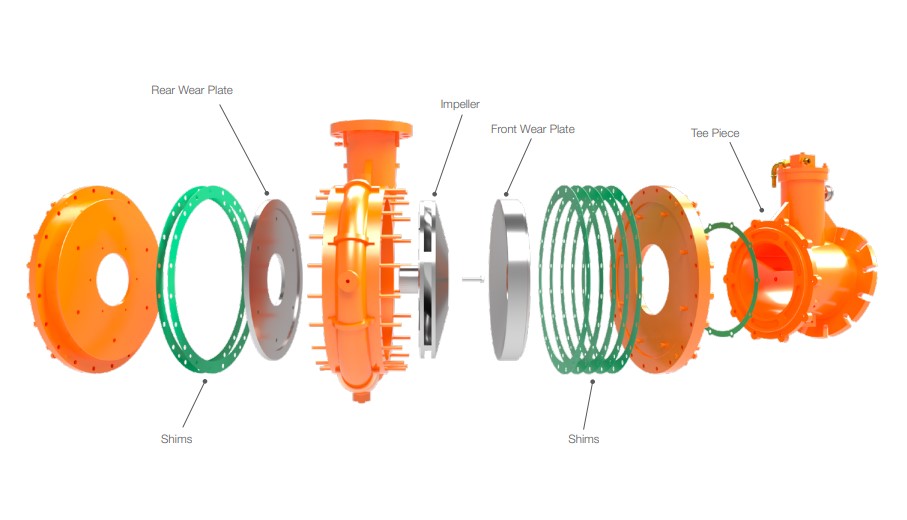

The Sykes XH250 pump represents a significant leap in dewatering technology. It has been able to improve flow capacity and extend the head capabilities, allowing pumps to reach total dynamic heads of up to 220 metres.

Many mining companies will be happy to hear the XH250 is not a ‘one-size-fits all’ product. You have the power to choose pump features to match your site conditions. These can include:

- Select diesel or electric in a variety of brands and sizes.

- Range of mounting options, including skid, trailer and pontoon/barge.

- Priming options such as compressor prime, diaphragm prime, anti-spit and vacuum prime.

One of the most discussed benefits of the XH250 is the shaft stiffness. With a ratio of 0.28, it surpasses industry standards and ensures plenty of resilience against shaft deflection.

While we have only scratched the surface of the XH250, it’s clear to see that it is a superior dewatering option for deep mining operations. Its versatility, power and pressure capability allow mines to reach their deep mining goals – minimising interruption due to water ingress and reducing the risk of damaging equipment or the safety of their workers.

To find out more about Sykes XH250 dewatering pumps, contact Sykes Group. All Sykes Pumps are manufactured in Australia and distributed globally. Our pumps can be found in operation across Asia, Africa, North and South America, Europe, Middle East and throughout Australia.